As cost pressures propagate from OEM’s down the value chain, does Industry 4.0 hold the solutions?

Québec, the source of 52% of the Canadian aerospace industry’s sales and home to 70% of R&D, holds a prominent position on the international stage, with 80% of its production exported. Montréal is Québec’s largest city and one of the world’s top three aerospace hubs, alongside Seattle and Toulouse.

The presence within the region of major international players such as Bell Helicopter Textron, Bombardier Aerospace, CAE and Pratt & Whitney Canada has laid the foundation for a prosperous sector. Alongside the Big Four, the plethora of SMEs across a variety of disciplines contribute to Québec’s vibrant aerospace ecosystem.

However, the sector has faced a number of challenges in recent years as in other parts of the world, which continue to shape the industry. Amid increasing cost pressure from the top of the value chain and a desire to simplify supply chains, SMEs must adapt in order to stay afloat. Consolidation seems inevitable as customers show preference for integrated service offerings from their suppliers. SMEs, whilst previously holding an advantage in terms of flexibility and specialized expertise, are struggling to compete.

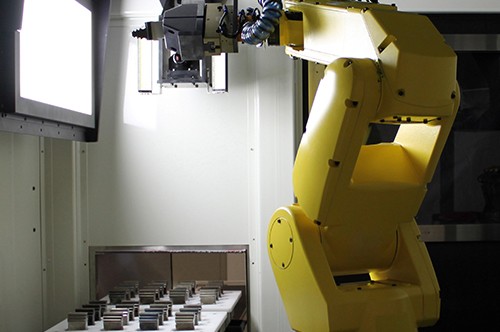

In response to the proliferation of cost pressures throughout the supply chain, companies are increasingly seeking to automate processes. Through optimization and increased operational efficiency, companies are driving cost reduction following the initial investment.

Used as an umbrella term for new(ish) technologies, “Industry 4.0” is a term uttered by many but generally lacking a solid definition. “There is a danger that Industry 4.0 could be viewed as ‘Industry 3.0’ on steroids, simply automation and digitization of manufacturing processes with bigger computers in order to produce things better, faster and cheaper,” noted Stephen Yue, Lorne Trottier Chair in Aerospace Engineering and director at McGill University’s Institute for Aerospace Engineering. “Production optimization is a continuous process; there is no need to label something that is naturally evolving. One major difference of 4.0 versus 3.0 is that it does not involve only manufacturing but digitally links together all aspects and associated technologies of the business, from ordering to delivery, and maybe beyond.”

The uptake of technologies facilitating automation, digitization, robotics, artificial intelligence, additive manufacturing and a general progression towards the Internet of Things has certainly increased, which is particularly notable in an industry that is historically conservative.

“Additive manufacturing in particular is a very interesting technology for our product,” commented Gilles Labbé, president and CEO at Héroux-Devtek. “In the forging of products, a very long lead time is required for building and obtaining parts from the supplier, plus the subsequent machining can result in wasting 80% of the material. Additive manufacturing reduces the long lead time and can reduce the material cost and waste by large amounts. It is now proven, with GE as a good example, that the additive manufacturing process can design lighter and more reliable components at a lesser cost. Additive manufacturing will become more and more present in our industry and will be a game changer.”

Héroux-Devtek is currently progressing in its contract for the Boeing 777 aircraft landing gear, which involved an investment of over $110 million on equipment and capacity and has installed flexible manufacturing systems (FMS) to automate the process. Through FMS, one employee can run four or five pieces of equipment simultaneously. The company also plans to be the first to employ robotics to paint these landing gear parts.

However, although promises of increased efficiency, quality and production are appealing, concerns remain over whether companies can support the required investment. Many SME’s not only lack the investment power, but also the production volumes required to justify the investment. SME’s wanting to implement these new technologies will therefore likely require the additional volumes found in exports, but may suffer from a competitive standpoint by not being able to offer these advantages in the first place.

The Québec government’s intention to address this challenge is apparent in its 2017-18 budget, which indicates planned investment of CAD$100 million over five years to develop Montreal as an artificial intelligence (AI) ‘supercluster’. At a national level, the federal government’s 2017-18 budget also shows focus on innovation, proposing the establishment of a new department, Innovation Canada, which will distribute investment of up to CAD$950 million into a number of ‘superclusters’ over the same five-year period.

Training for Implementation

As universities continue to position themselves as partners to industry and play a more proactive role in securing practical experience for students, they will be integral in the training of new talent to support these technology trends. Although some concerns may be raised around potential job loss, consensus seems to be that whilst the nature of certain roles may change, robotics and other new technologies will enhance performance across various aspects rather than replace any need for human judgement.

According to the Comité sectoriel de main d’oeuvre en aérospatiale du Québec (CAMAQ), the Québec Aerospace Workforce Sector Committee, the region will need 10,000 new aerospace employees over the next 10 years and a further 23,000 to replace workers leaving the workforce.

“There are also many opportunities within Industry 4.0, or “Aerospace 4.0”,” highlighted Dr. Hany Moustapha, professor and director at AÉROÉTS, Pratt & Whitney Canada (P&WC) Chair in propulsion systems at École de technologie supérieure (ÉTS) and senior research fellow at P&WC. “A key challenge is to demystify these concepts, for which we are offering short courses and presentations at ÉTS. Industry 4.0 encompasses entire processes and we will therefore need to develop these capabilities within the workforce. As well as supporting our students, we will continue to work with companies of all shapes and sizes.”

ÉTS prides itself on its strong industry links; by placing more than 3,000 interns at companies every year, the university ensures its students have the practical experience preferred and often demanded by companies. In addition, ÉTS conducts 70% of research activities in collaboration with industry, a huge leap from the Canadian average of 25%.

Industry 4.0 in the future

Industry 4.0 presents a means to achieve results that were not previously achievable. The advantages of automating certain processes, for example, are clear; higher accuracy, shorter lead times and generally increased efficiency are just some of the incentives to invest. However, the investment required may knock out some players if they cannot keep up with their competitors.

For an industry that exports such a huge majority of its production, it is in the region’s interest to support the technological transformation of its companies. Remaining competitive at an international level is paramount and implementation of automation and digitization processes are a step in closing the gap with low-cost jurisdictions

Québec, the source of 52% of the Canadian aerospace industry’s sales and home to 70% of R&D, holds a prominent position on the international stage, with 80% of its production exported. Montréal is Québec’s largest city and one of the world’s top three aerospace hubs, alongside Seattle and Toulouse.

The presence within the region of major international players such as Bell Helicopter Textron, Bombardier Aerospace, CAE and Pratt & Whitney Canada has laid the foundation for a prosperous sector. Alongside the Big Four, the plethora of SMEs across a variety of disciplines contribute to Québec’s vibrant aerospace ecosystem.

However, the sector has faced a number of challenges in recent years as in other parts of the world, which continue to shape the industry. Amid increasing cost pressure from the top of the value chain and a desire to simplify supply chains, SMEs must adapt in order to stay afloat. Consolidation seems inevitable as customers show preference for integrated service offerings from their suppliers. SMEs, whilst previously holding an advantage in terms of flexibility and specialized expertise, are struggling to compete.

In response to the proliferation of cost pressures throughout the supply chain, companies are increasingly seeking to automate processes. Through optimization and increased operational efficiency, companies are driving cost reduction following the initial investment.

Used as an umbrella term for new(ish) technologies, “Industry 4.0” is a term uttered by many but generally lacking a solid definition. “There is a danger that Industry 4.0 could be viewed as ‘Industry 3.0’ on steroids, simply automation and digitization of manufacturing processes with bigger computers in order to produce things better, faster and cheaper,” noted Stephen Yue, Lorne Trottier Chair in Aerospace Engineering and director at McGill University’s Institute for Aerospace Engineering. “Production optimization is a continuous process; there is no need to label something that is naturally evolving. One major difference of 4.0 versus 3.0 is that it does not involve only manufacturing but digitally links together all aspects and associated technologies of the business, from ordering to delivery, and maybe beyond.”

The uptake of technologies facilitating automation, digitization, robotics, artificial intelligence, additive manufacturing and a general progression towards the Internet of Things has certainly increased, which is particularly notable in an industry that is historically conservative.

“Additive manufacturing in particular is a very interesting technology for our product,” commented Gilles Labbé, president and CEO at Héroux-Devtek. “In the forging of products, a very long lead time is required for building and obtaining parts from the supplier, plus the subsequent machining can result in wasting 80% of the material. Additive manufacturing reduces the long lead time and can reduce the material cost and waste by large amounts. It is now proven, with GE as a good example, that the additive manufacturing process can design lighter and more reliable components at a lesser cost. Additive manufacturing will become more and more present in our industry and will be a game changer.”

Héroux-Devtek is currently progressing in its contract for the Boeing 777 aircraft landing gear, which involved an investment of over $110 million on equipment and capacity and has installed flexible manufacturing systems (FMS) to automate the process. Through FMS, one employee can run four or five pieces of equipment simultaneously. The company also plans to be the first to employ robotics to paint these landing gear parts.

However, although promises of increased efficiency, quality and production are appealing, concerns remain over whether companies can support the required investment. Many SME’s not only lack the investment power, but also the production volumes required to justify the investment. SME’s wanting to implement these new technologies will therefore likely require the additional volumes found in exports, but may suffer from a competitive standpoint by not being able to offer these advantages in the first place.

The Québec government’s intention to address this challenge is apparent in its 2017-18 budget, which indicates planned investment of CAD$100 million over five years to develop Montreal as an artificial intelligence (AI) ‘supercluster’. At a national level, the federal government’s 2017-18 budget also shows focus on innovation, proposing the establishment of a new department, Innovation Canada, which will distribute investment of up to CAD$950 million into a number of ‘superclusters’ over the same five-year period.

Training for Implementation

As universities continue to position themselves as partners to industry and play a more proactive role in securing practical experience for students, they will be integral in the training of new talent to support these technology trends. Although some concerns may be raised around potential job loss, consensus seems to be that whilst the nature of certain roles may change, robotics and other new technologies will enhance performance across various aspects rather than replace any need for human judgement.

According to the Comité sectoriel de main d’oeuvre en aérospatiale du Québec (CAMAQ), the Québec Aerospace Workforce Sector Committee, the region will need 10,000 new aerospace employees over the next 10 years and a further 23,000 to replace workers leaving the workforce.

“There are also many opportunities within Industry 4.0, or “Aerospace 4.0”,” highlighted Dr. Hany Moustapha, professor and director at AÉROÉTS, Pratt & Whitney Canada (P&WC) Chair in propulsion systems at École de technologie supérieure (ÉTS) and senior research fellow at P&WC. “A key challenge is to demystify these concepts, for which we are offering short courses and presentations at ÉTS. Industry 4.0 encompasses entire processes and we will therefore need to develop these capabilities within the workforce. As well as supporting our students, we will continue to work with companies of all shapes and sizes.”

ÉTS prides itself on its strong industry links; by placing more than 3,000 interns at companies every year, the university ensures its students have the practical experience preferred and often demanded by companies. In addition, ÉTS conducts 70% of research activities in collaboration with industry, a huge leap from the Canadian average of 25%.

Industry 4.0 in the future

Industry 4.0 presents a means to achieve results that were not previously achievable. The advantages of automating certain processes, for example, are clear; higher accuracy, shorter lead times and generally increased efficiency are just some of the incentives to invest. However, the investment required may knock out some players if they cannot keep up with their competitors.

For an industry that exports such a huge majority of its production, it is in the region’s interest to support the technological transformation of its companies. Remaining competitive at an international level is paramount and implementation of automation and digitization processes are a step in closing the gap with low-cost jurisdictions